Since 1937, manufacturers nationwide have depended on Wingfield’s equipment and service for instant and accurate measurements.

Solutions

Wingfield provides the tools and expertise companies need to weigh, measure, and count at every stage of the manufacturing process.

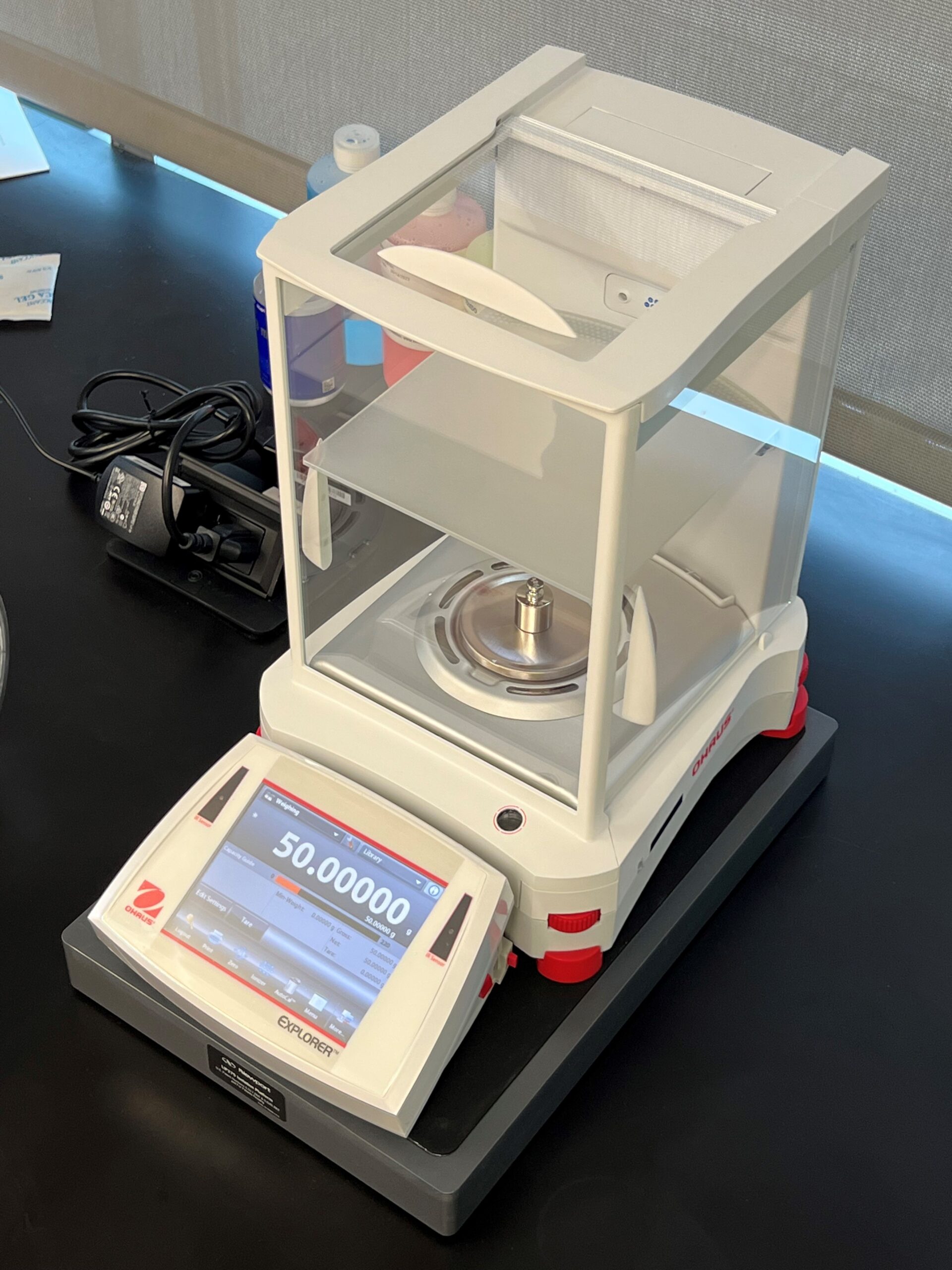

Scales

Wingfield provides manufacturers with scales for accurate measurements whether its raw materials or finished products

Map & Measure

We offer innovative solutions enabling you to accurately measure and map your mine, plant, and facilities.

Rental

We have the largest fleet of rental scales in the country, engineered to provide accurate measurement for every context.

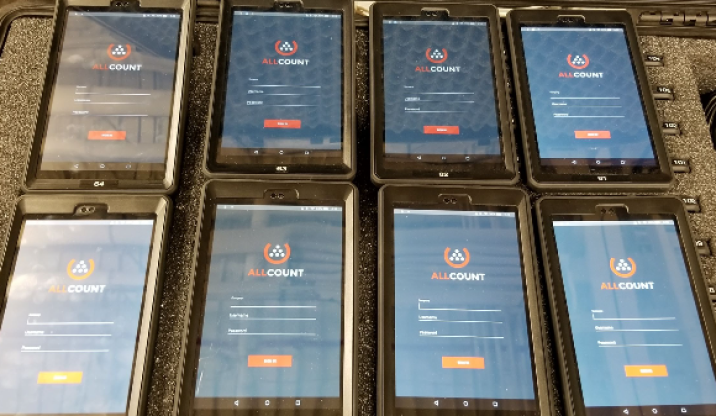

Inventory

Track your inventory faster and more accurately with Wingfield’s innovative tools designed for inventory management.

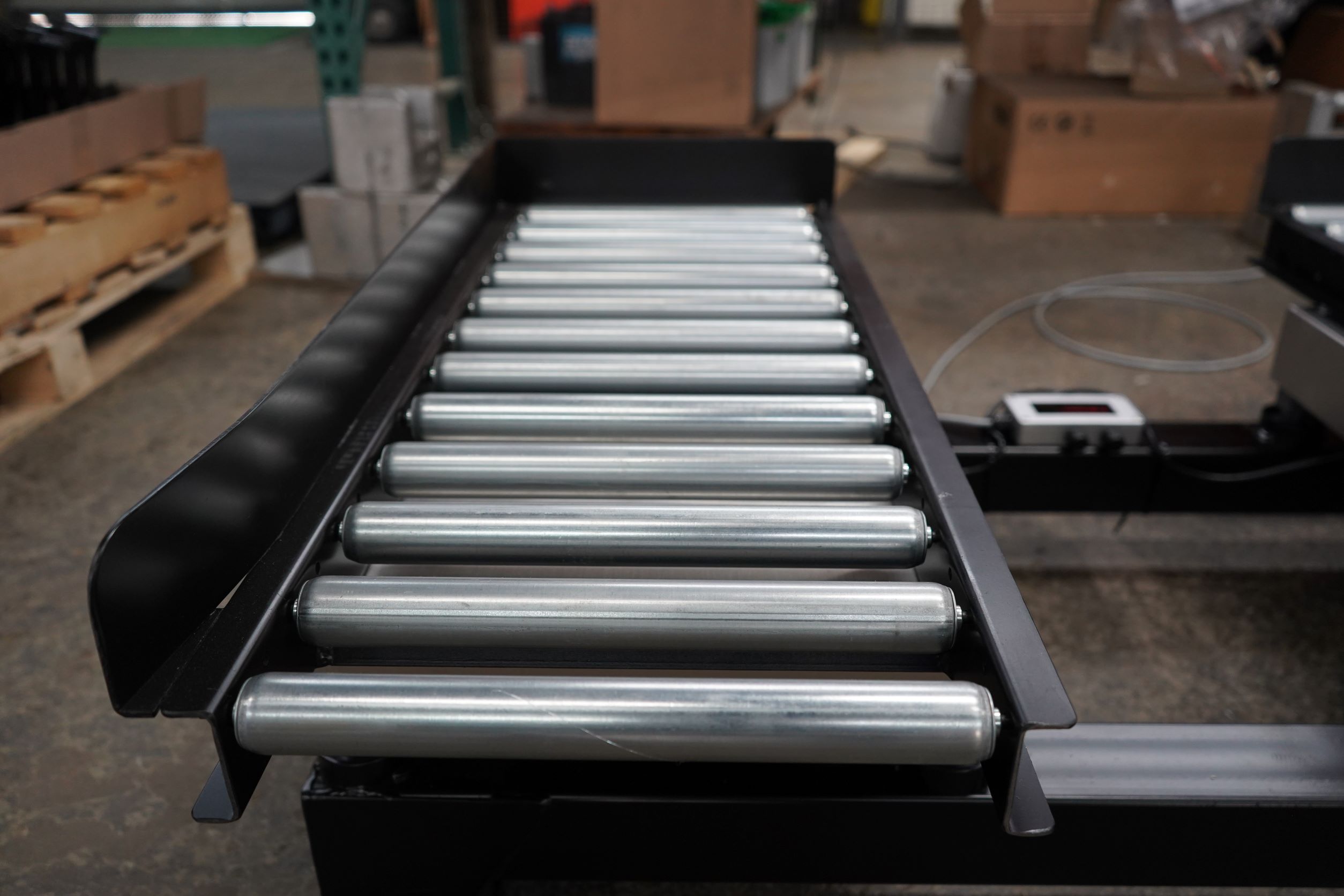

WingScan

Our volumetric load scanner provides you the ability to accurately and instantly measure materials in motion

Service & Calibration

Our certified technicians keep your equipment working so you can avoid disruptions in the manufacturing process.

Experience

Trusted by America’s leading manufacturers for over 87 years.

Industries

Wingfield serves companies at every point of the supply chain and manufacturing process, whether you are working with raw materials or a finished product.

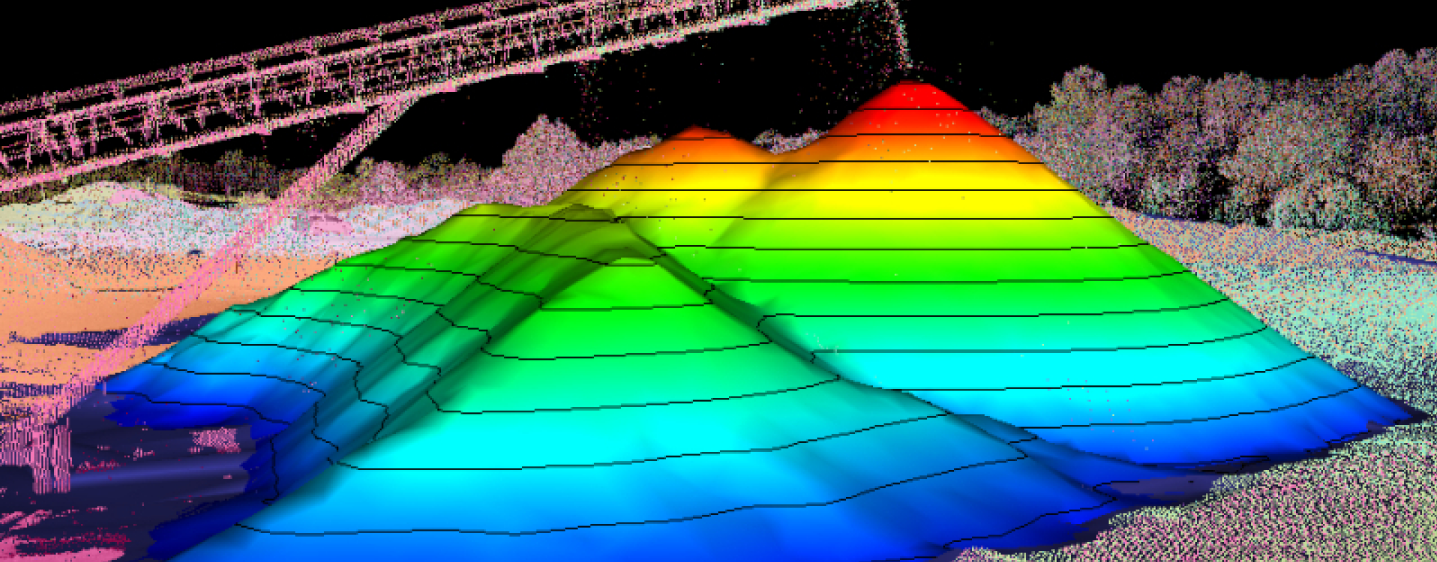

NEW VOLUME LOAD SCANNER

WingScan Advanced LiDAR Technology

WingScan products have been developed to track bulk material via conveyor belt, truck, or railcar. These LiDAR load scanners provide real-time remote material monitoring utilizing a single control via secure, intuitive interface options.

Wingfield on the Road

Here are trade shows and events we are attending. Please let us know if you will be there as well so that we may connect with you.

-

Geo Week 2024

February 11-13, 2024

Denver, CO

-

Georgia Construction Aggregates Association (GCAA)

February 20-22, 2024

Atlanta, GA

-

MINEXCHANGE 2024 SME Annual Conference & Expo

February 25-28, 2024

Phoenix, AZ

-

AGG 1

March 25-27, 2024

Nashville, TN

-

Commercial UAV Expo

September 3-5, 2024

Las Vegas, NV

-

Mine Expo International

September 24-26, 2024

Las Vegas, NV

-

Kentucky Crushed Stone

Date: TBD (early December)

Louisville, KY